Call Us

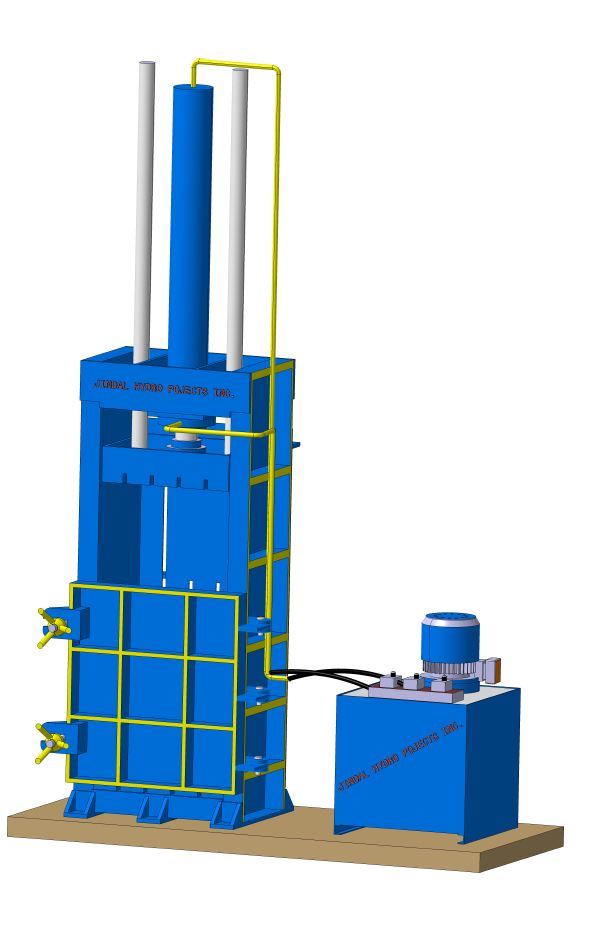

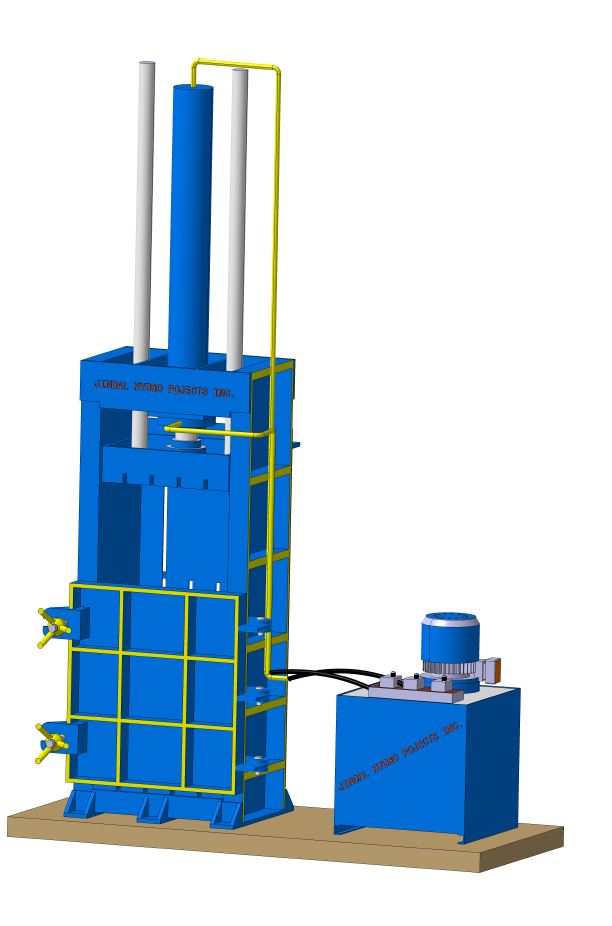

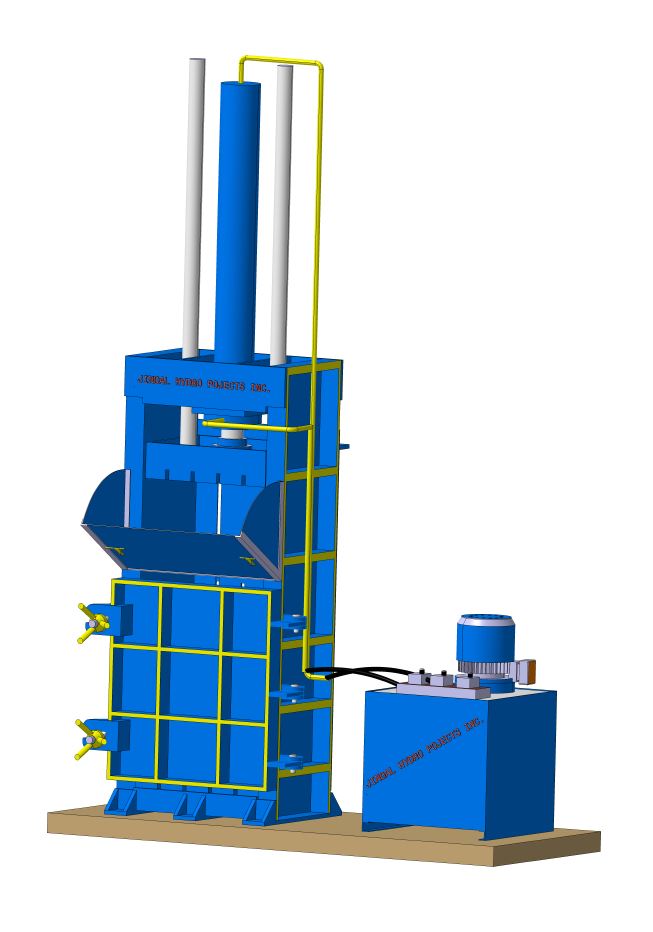

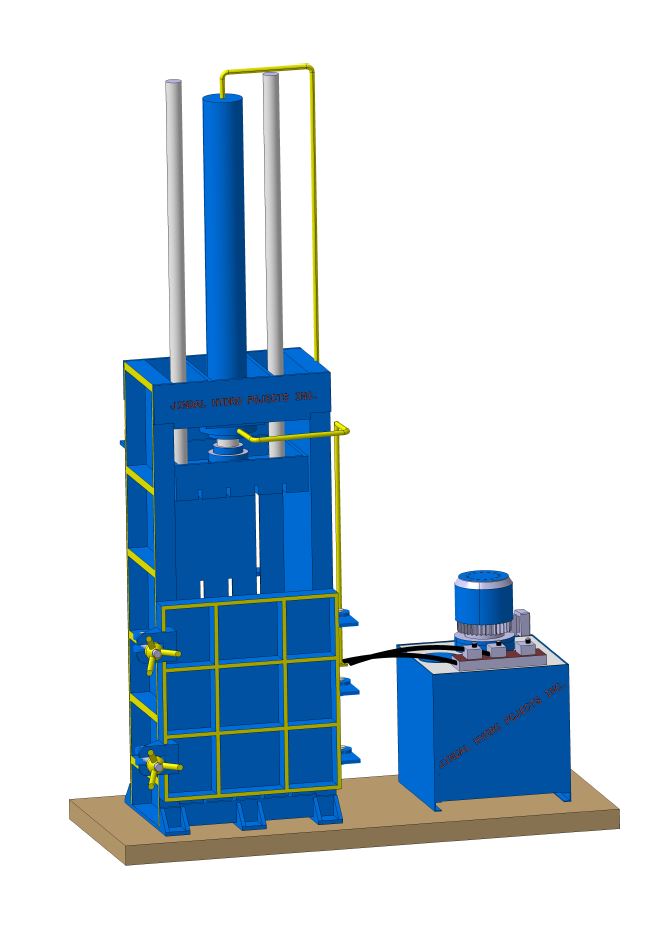

08045811645Single Box Double Door Hydraulic Baling Press Machine

425000.0 INR/Piece

Product Details:

- Nominal Force requirement based

- Usage Industrial

- Power Source Hydraulic

- Size 22x27x60 inch

- Condition New

- Dimension (L*W*H) 22x27x60 Inch (in)

- Height 60 Inch (in)

- Click to View more

X

Single Box Double Door Hydraulic Baling Press Machine Price And Quantity

- 1 Piece

- 425000.0 INR/Piece

Single Box Double Door Hydraulic Baling Press Machine Product Specifications

- 60 Inch (in)

- Blue

- H Frame Hydraulic Press Machine

- 22 Inch (in)

- Hydraulic

- provided

- 22x27x60 Inch (in)

- 220-240 Volt (v)

- New

- 10 h.p

- 22x27x60 inch

- 2000 Kilograms (kg)

- 10 Horsepower (HP)

- 27 Inch (in)

- requirement based

- Industrial

Single Box Double Door Hydraulic Baling Press Machine Trade Information

- requirement based

- Cash in Advance (CID)

- 10 Piece Per Month

- 1 Week

- No

- Sample costs shipping and taxes has to be paid by the buyer

- Terms and Conditions Delivery Within 15 Days from the date of receipt your confirmation order copy duly signed and stamped along with advance payment. Terms of Payments 50% as advance along with the order & balance 50% against Performa invoice prior to dispatch along with forms. Taxes & Duties extra All the Govt. / Local Taxes and duties shall be charged extra at the prevailing rate at the time of dispatch. However present rates of taxes are as follows: IGST: IGST 18% HSSN CODE: - 8462 Forwarding Charges Prices are based on the cost of material, component, labour and statutory obligations ruling at the date of tender or contact and may be revised and varied by JHP should these price increase. Such increase may be based by JHP on the market price of raw materials and components. Unless otherwise agreed prices are strictly ex-JHP Works and do not include the cost of packing, carriage, freight and insurance which will be charged to or paid by the Buyer. If amicably decided then the Company will arrange for packing of the goods on behalf of the Buyer at an extra charge of @ 10% Inspection Inspection can be carried out at our works prior to dispatch if so desired by you. Dispatch All the Company s goods are forwarded at the Buyer s own risk. In case of goods for export or goods sold delivery ex the Company s Works the Company cannot accept responsibility for damage or delay during transit unless it has specifically agreed in writing to cover such risk by insurance Performance, Weight, Measurement and Power Although carefully computed, must be considered approximate only and are not guarantee. Force Majure If either party is delayed or hindered in or prevented from performing any of its obligations under the Agreement by reason of act of God, fire, flood, accident, explosion, breakdown or failure of plant or machinery, war, riot, civil disturbance, strike, labour dispute, acts, orders, or regulations of Government failure (whether partial or total) of or shortage in any of the Company s or its suppliers existing or contemplated sources of material (including parts & components) or fuel or labour or transport whether such failure or shortage be existing or apprehended by the Company, failure of any supplier or sub-contractor with the Company or by reason of any cause whether or not of the same nature as the foregoing beyond its control, it shall be under no liability to the other in respect of non-performance of such obligation but the time for performing the same shall be extended until the operation of causes preventing, hindering or delaying the performance thereof has ceased. Warranty The offered equipment shall be guaranteed for a period of 12 months from the date of its dispatch against and manufacturing defect only. However, warranty does not cover against misuse, mishandling, improper maintence rubber & electrical parts and brought out items. Special Note Once order is placed the buyer cannot be cancel the order, if cancellation is done no refund of Advance payment would be claimed from seller at any cost. Arbitration 1. All disputes or differences arising in future between the parties relating to this quotation shall be referred for arbitration in accordance with the provisions of the arbitration and conciliation act, 1996 based at Alwar, Rajasthan. The award made in pursuance to that shall be binding on both the parties. The sales against this quotation shall be continued during arbitration proceedings unless it is reasoned that the sales cannot possibly be continued till the matter is finally decided by the appointed arbitrators, no payment due to the company shall be withheld on account of such arbitration proceedings, unless it is the subject matter or one of the subject matters thereof, The supplier shall not pay any interest, damages (including liquidated risk purchase) etc. for non-delivery of material for the reasons beyond its control. 2. Appointment of Arbitrator Each party shall appoint one (1) arbitrator and these two (2) arbitrators shall jointly agree on and appoint the third arbitrator. If the two (2) arbitrators appointed cannot agree on a third arbitrator, the third arbitrator shall be appointed in accordance with the provisions of the arbitrations and conciliation Act, 1996 and any amendment/thereof. 3. The Language of arbitration shall be English only. 4. Binding and Liability. The award pass by the arbitrator(s) shall be binding and the sole and exclusive remedy between the parties regarding any dispute and all claims or counterclaims for the parties, their successors and assign and each shall comply in good faith with any and all rulings of the arbitrators. Installation & Commissioning 1. Exaction of the machine cable laying & termination to be done by the customers as per our specification. 2. Installation, commissioning & servicing under warranty period is free of cost only you have to bear to&Fro AC Train fare along with loading & boarding. 3. After warranty the charges of the engineer is 5000/- per day (A day is considered to be a 8 hours working hour) plus To &Fro AC Train fare with loading & boarding. 4. In case of Export all the expenses (Visa, Air Ticket, Hotel, and Local Fare Ec.) will be charge extra. Validity of the offer 30 days from the date of dispatch. All disputes subject to only Alwar Jurisdiction. [NOTE: ANY OTHER CLAUSE, WHICH IS NOT MENTIONED IN OUR OFFER, SHALL NOT BE BINDING ON US UNLESS AGREED BY US IN WRITING.] Thanking you, & awaiting your valued order. Yours faithfully For Jindal Hydro Projects Inc. Rakesh Gupta +91-986817694

- Asia

- All India

Product Description

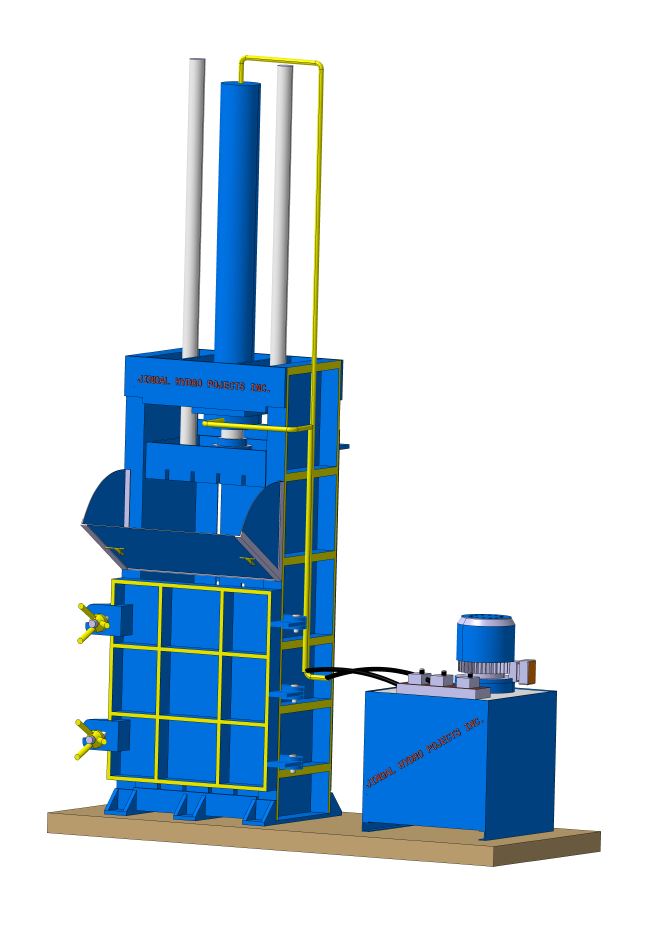

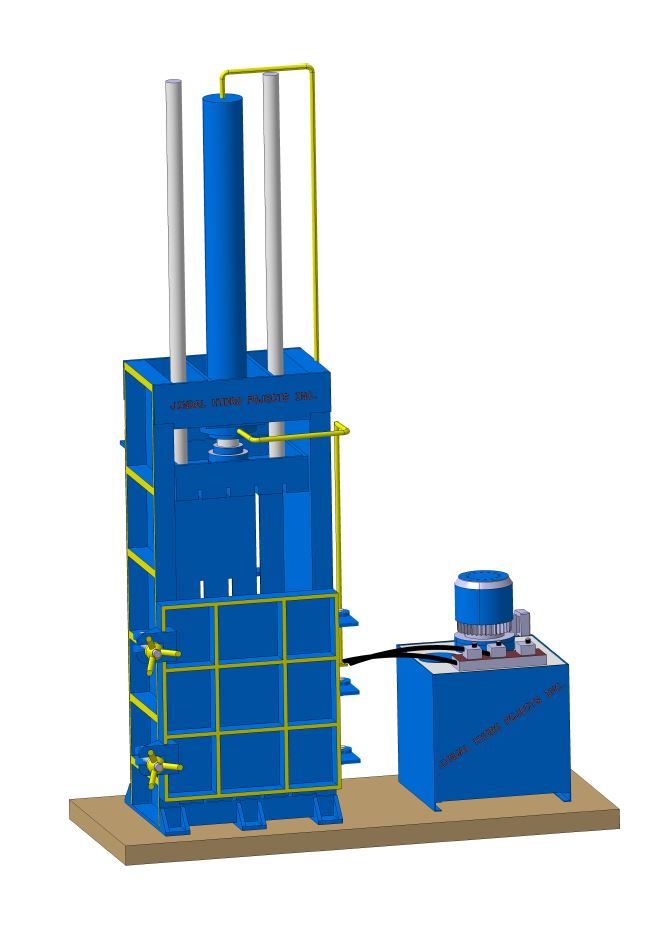

Single Box Double Door Hydraulic Bailing Press Machine is made with high-quality raw materials that are purchased from reputable vendors in the market. Our product line is available in a variety of specifications that can be tailored to meet the needs of our customers. This machine is very easy to handle and simple to work on. Single Box Double Door Hydraulic Bailing Press Machine is specifically developed to satisfy the bailing requirements of pet bottles and waste paper, successfully handle the feed materials compression demands and aid in the conversion of the feed into compact bales for shipment.Powerful Hydraulic Performance

Equipped with a 10 horsepower motor and hydraulic power source, the machine delivers consistent compressive force for effective baling. The pressure gauge ensures operational safety, and pre-fill, proportional, and solenoid valve options are available according to your requirements.

Customizable Design for Diverse Needs

Our baling press machine can be customized in terms of color and integrated with PLC systems or valves as requested. It offers a nominal force and operational flexibility, making it suitable for various industrial applications and material types.

Efficient Industrial Usage

This machine is ideal for manufacturing, supplier operations, and industrial waste management. Its compact size (22x27x60 inches), efficient baling process, and easy maintenance make it a top choice for facilities aiming to optimize storage and transportation of compacted goods.

FAQs of Single Box Double Door Hydraulic Baling Press Machine:

Q: How does the Single Box Double Door Hydraulic Baling Press Machine operate?

A: The machine utilizes hydraulic pressure powered by a 10 h.p motor to compact materials efficiently. The process involves loading materials into the box, closing the double doors, and initiating the baling cycle using the hydraulic system.Q: What types of industries can benefit from this baling press machine?

A: This machine is ideal for manufacturing, supplier operations, and industrial waste management sectors. It efficiently compresses various materials, making it suitable for compacting scrap, recyclable materials, and industrial by-products.Q: Where can the machine be installed, considering its size and weight?

A: With dimensions of 22x27x60 inches and a weight of 2000 kg, the machine requires a stable, level industrial workspace with sufficient space for installation and operation. It is designed to fit into compact production areas without compromising performance.Q: When is the optimal time to use this baling press?

A: The machine is best utilized during routine industrial processes when materials accumulate and require compaction, such as at the end of production cycles or during scheduled waste management intervals.Q: What is the process for customizing features like color and PLC system?

A: Customers can specify their requirements for color, PLC systems, and additional valves at the time of ordering. The manufacturer will integrate these customizations as per your specifications before delivery.Q: How does the hydraulic baling press contribute to operational efficiency?

A: By compacting and reducing material volume, the machine helps optimize storage space and simplifies transportation. Its automated hydraulic mechanism ensures consistent results, reducing manual labor and operational delays.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

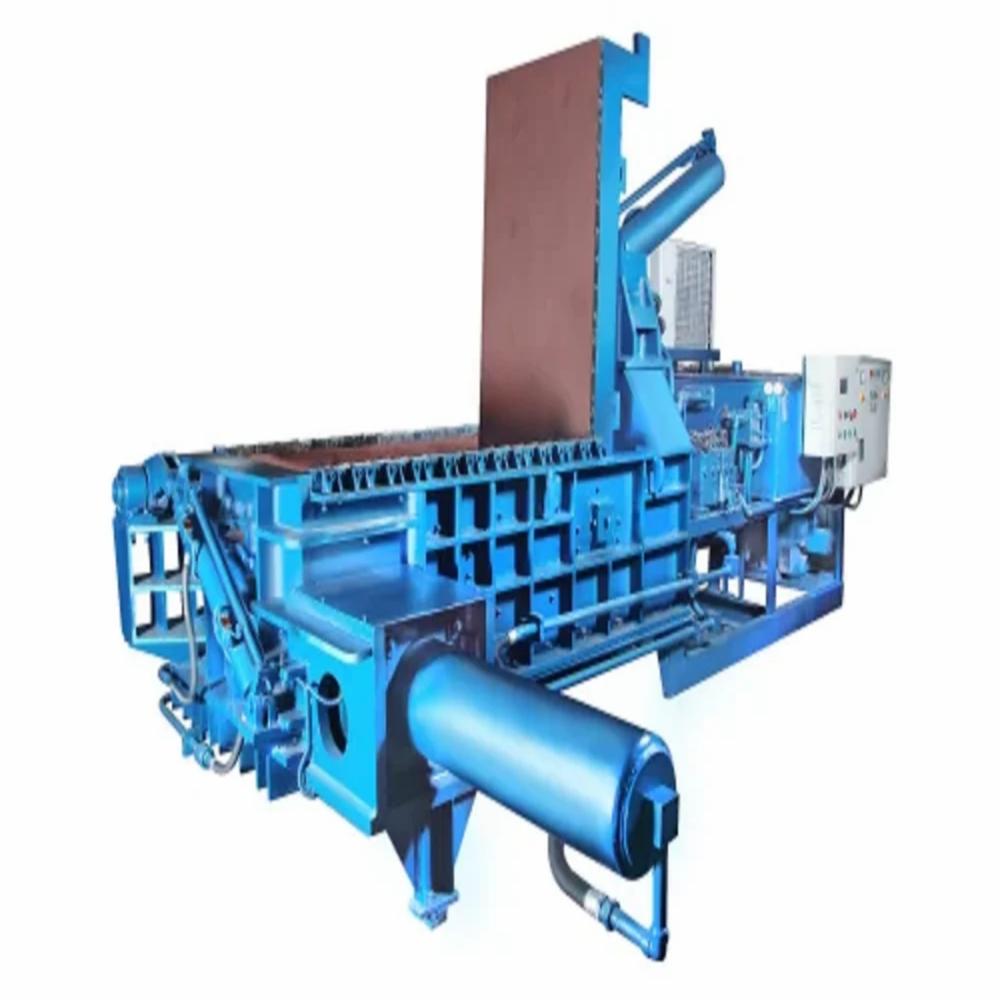

Other Products in 'Hydraulic Baling Press Machine' category

"We are mainly looking for International Inquiries. We are looking for more inquires related to balling products"

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free