Call Us

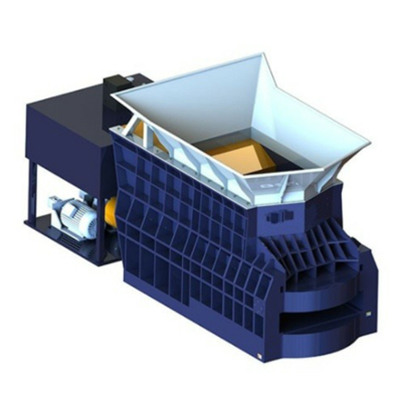

08045811645Box Shear Machine

1500000 INR/Unit

Product Details:

- Connectivity Options Remote diagnostics (optional)

- Noise Level Below 80 dB db

- Cooling System Oil Cooling System

- Model No BXS-315T

- Operating Temperature 5C - 45C Celsius (oC)

- Accuracy 1 mm mm

- Production Capacity Up to 10 tons/hour T/hr

- Click to View more

X

Box Shear Machine Price And Quantity

- 1 Unit

- 1500000 INR/Unit

Box Shear Machine Product Specifications

- Hydraulic Shearing

- Hydraulic Drive

- 45 HP Horsepower (HP)

- Up to 10 tons/hour T/hr

- 1 mm mm

- 5C - 45C Celsius (oC)

- Industrial Blue/Grey

- 45 kW Watt (w)

- Painted

- 315 Ton kgf/cm2

- Remote diagnostics (optional)

- Below 80 dB db

- BXS-315T

- 18000 kg Kilograms (kg)

- Scrap shearing, Metal recycling, Steel processing

- Box Shear Machine

- Oil Cooling System

- 7500 x 2600 x 3200 mm Millimeter (mm)

- 380 V - 440 V Volt (v)

- Box Type Shear

- Automatic

- Box Welded Frame

- 50 Hz Hertz (HZ)

- Heavy duty, High efficiency, Low power consumption

- Electric

- Three Phase

- Centralized lubrication

Box Shear Machine Trade Information

- 10 Unit Per Month

- 1 Months

Product Description

Box shear machine, also known as a squaring shear or a sheet metal shear, is a machine tool used to cut and shape sheet metal into various sizes and shapes. The box shear machine consists of a cutting blade that moves vertically or horizontally along a fixed blade, creating a shearing action that cuts the metal. The machine can cut straight lines, curved lines, and angles, and can be used to produce a variety of products, such as brackets, panels, and enclosures. The machine can also be used to trim excess material from metal sheets or to create clean, precise edges. Box shear machines come in various sizes and can be manually operated or computer-controlled for greater precision and efficiency. It is important to follow proper safety procedures when operating a box shear machine to avoid injury or damage to the equipment.

Exceptional Cutting Performance

Equipped with a powerful 350 mm main cylinder and a hardened alloy steel cutting blade, the Box Shear Machine delivers top-tier performance for processing various metal scraps. The hydraulic system ensures clean, reliable cuts with each cycle, maintaining an impressive accuracy of 1 mm while working quietly below 80 dB.

Advanced Safety and Convenience Features

This machine incorporates comprehensive safety protections, such as overload, earth fault, and phase reversal safety mechanisms, plus an accessible emergency stop. Its PLC-based control system allows easy operation via push button or remote controls, while optional remote diagnostics maximize operational convenience and uptime.

Designed for Heavy Duty Industrial Use

Built with a robust box welded frame and durable surface treatments, the BXS-315T thrives in tough environments. It also includes centralized lubrication and an oil cooling system to ensure long-term reliability. With a 45 kW motor and hydraulic drive, it efficiently handles large scrap volumes, supporting production demands in recycling centers and steel processing plants.

FAQ's of Box Shear Machine:

Q: How does the BXS-315T Box Shear Machine operate and control the cutting process?

A: The BXS-315T operates via push button or remote controls and is managed by a PLC control system, allowing for automatic and precise hydraulic shearing of metal scraps. Operators can monitor the process and make quick adjustments as needed.Q: What materials and scrap sizes can the machine handle efficiently?

A: This machine is designed for processing a variety of metal scraps, supporting material dimensions up to 1200 x 600 mm. The hardened alloy steel blade and 600 mm shearing width ensure efficient cutting of diverse scrap types in recycling and steel processing environments.Q: When should regular maintenance and checks be performed on the machine?

A: Routine maintenance is recommended according to the manufacturer's guidelines, typically after a determined number of operating hours. This includes checking the central lubrication system, oil cooling, hydraulic fluid levels, and inspecting safety features for optimal performance.Q: Where is the Box Shear Machine best utilized?

A: The BXS-315T is ideal for use in metal recycling centers, steel processing facilities, and industrial scrap yards where large volumes of metal scraps need to be sheared efficiently and safely.Q: What is the process flow for a standard cutting operation with this equipment?

A: The operator loads the scrap metal onto the machine, selects the cutting mode via PLC, and initiates the shearing process using the push button or remote. The hydraulic system cycles the blade to cut, with each stroke controlled for accuracy and safety, and processed material can be collected for further handling.Q: How does the machine ensure operational safety during use?

A: Safety is maintained through multiple integrated protections, including overload, earth fault, and phase reversal safeguards, as well as an emergency stop button. These features protect operators and machinery from unexpected faults or hazards.Q: What are the benefits of using the BXS-315T for industrial scrap shearing?

A: The BXS-315T offers high efficiency, low power consumption, superior operational accuracy (1 mm), and safe, user-friendly controls. Its high production capacity and heavy-duty construction reduce downtime and maintenance costs, providing a reliable solution for demanding industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Scrap Baler Machine' category

"We are mainly looking for International Inquiries. We are looking for more inquires related to balling products"

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese