Call Us

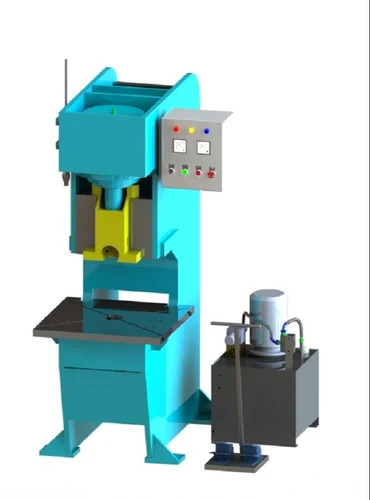

08045811645C Frame Throat Hydraulic Presses

Product Details:

- Nominal Force requirement based

- Usage Industrial

- Power Source Hydraulic

- Product Type C Frame Throat Hydraulic Presses

- Color Blue

- Motor requirement based

- PLC System requirement based

- Click to View more

C Frame Throat Hydraulic Presses Price And Quantity

- 1 Unit

- 1000000 INR/Unit

C Frame Throat Hydraulic Presses Product Specifications

- requirement based

- Industrial

- requirement based

- C Frame Throat Hydraulic Presses

- requirement based

- requirement based

- requirement based

- Hydraulic

- requirement based

- requirement based

- Blue

- requirement based

C Frame Throat Hydraulic Presses Trade Information

- requirement based

- Cash in Advance (CID)

- 10 Unit Per Month

- 1 Months

- Sample costs shipping and taxes has to be paid by the buyer

- poly pack

- Asia

- All India

Product Description

C Frame Throat Hydraulic Presses are frequently utilized in the fabrication of small components for a range of applications. Our presses are designed with good aesthetics and ergonomics in mind for a professional appearance and operator comfort. These presses can be tailored to meet your specific needs. Our offered C Frame Throat Hydraulic Presses are very light weighted, economical and durable in nature. Stamping, bending, flanging, straightening, drawing, and other metal material stamping operations are all possible with the C frame press machine. This is very effective to use.

Product details

|

Automatic Type |

Automatic |

|

Condition |

New |

|

Efficiency |

High |

|

Quality |

High |

|

Usage |

Industrial |

|

Capacity |

300 tons |

|

Power Source |

Hydraulic |

Custom-Built for Versatility

Every C Frame Throat Hydraulic Press we offer is designed to fit unique industrial needs. From the working table size and nominal force to the integration of specialized valves and PLC controls, each configuration is tailored per client requirements. This adaptability ensures high utility across various production lines and manufacturing environments.

Integrated Technology for Precision

Our hydraulic presses incorporate advanced features, including pressure gauges and proportional valves, which allow for meticulous control of force and accuracy during operations. The inclusion of PLC systems further enables automated and programmable usage, enhancing the overall productivity and repeatability on the shop floor.

FAQ's of C Frame Throat Hydraulic Presses:

Q: How can the working table size of the C Frame Throat Hydraulic Press be customized?

A: The working table size can be precisely tailored based on your specific operational requirements. During the consultation phase, our team collaborates with clients to determine necessary dimensions, ensuring the press accommodates your intended projects and materials.Q: What benefits do the proportional valve and PLC system offer?

A: The proportional valve adds fine-tuned hydraulic control, allowing for variable force application. Meanwhile, the PLC system enables programmable and automated press operations, improving process consistency, reducing errors, and increasing overall productivity.Q: When should you choose a hydraulic press with a designated nominal force and pressure gauge?

A: You should select a nominal force and pressure gauge that suit the demands of your industrial application. These specifications are determined during the planning process, ensuring ideal force delivery and accurate pressure monitoring for your tasks.Q: Where are the C Frame Throat Hydraulic Presses manufactured and supplied from?

A: Our presses are manufactured and supplied from India, where we operate as a leading exporter, manufacturer, and supplier. We serve industrial clients across local and international markets, delivering quality and customized hydraulic solutions.Q: What is the typical process for ordering and installing a customized hydraulic press?

A: The process starts with an assessment of your requirements, followed by technical consultation and design customization. After manufacturing, we assist with delivery, installation, and provide operational training to ensure optimal usage and maintenance.Q: How does the solenoid and pre-fill valve combination enhance press efficiency?

A: Solenoid and pre-fill valves work together to regulate fluid flow and expedite press action cycles. This configuration reduces cycle times and improves overall machine efficiency, especially in high-throughput industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free