Call Us

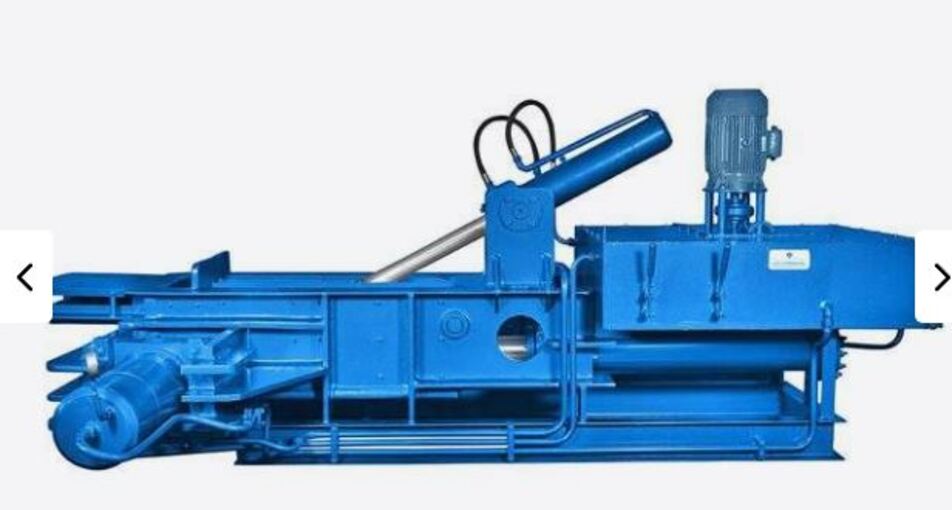

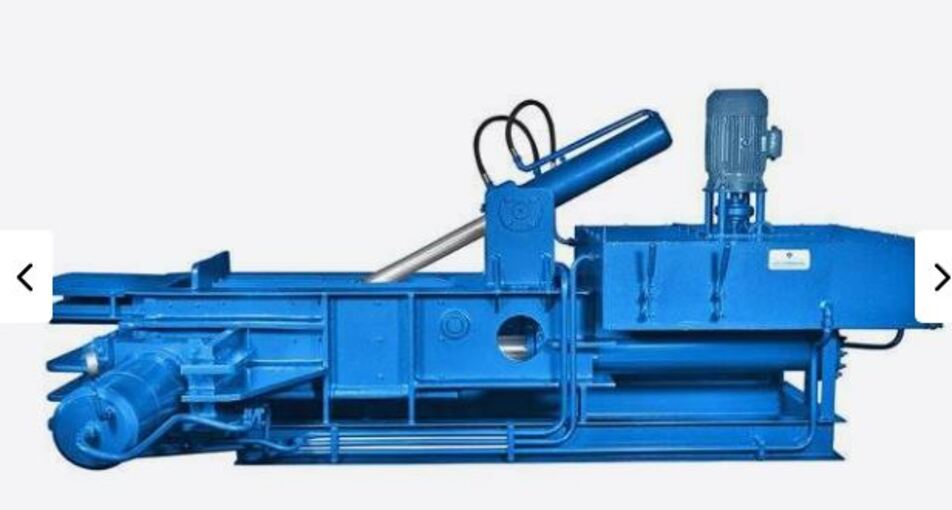

08045811645Triple Compression

Product Details:

- Nominal Force 100 TON

- Power Source Hydraulic

- Size 20x24x45"

- Dimension (L*W*H) 20x24x45" Inch (in)

- Height 24 Inch (in)

- Weight 8000 Kilograms (kg)

- Power(W) 25 Horsepower (HP)

- Click to View more

Triple Compression Price And Quantity

- 1200000.0 INR/Piece

- 1 Unit

Triple Compression Product Specifications

- 20x24x45"

- 240 Volt (v)

- Hydraulic

- 25 Horsepower (HP)

- 20 Inch (in)

- 100 TON

- 25

- 20x24x45" Inch (in)

- 45 Inch (in)

- 8000 Kilograms (kg)

- 24 Inch (in)

Triple Compression Trade Information

- requirement based

- Cash in Advance (CID)

- 10 Unit Per Month

- 1 Days

- No

- Sample costs shipping and taxes has to be paid by the buyer

- Delivery Within 15 Days from the date of receipt your confirmation order copy duly signed and stamped along with advance payment. Terms of Payments 50% as advance along with the order & balance 50% against Performa invoice prior to dispatch along with forms. Taxes & Duties extra All the Govt. / Local Taxes and duties shall be charged extra at the prevailing rate at the time of dispatch. However present rates of taxes are as follows: IGST: IGST 18% HSSN CODE: - 8462 Forwarding Charges Prices are based on the cost of material, component, labour and statutory obligations ruling at the date of tender or contact and may be revised and varied by JHP should these price increase. Such increase may be based by JHP on the market price of raw materials and components. Unless otherwise agreed prices are strictly ex-JHP Works and do not include the cost of packing, carriage, freight and insurance which will be charged to or paid by the Buyer. If amicably decided then the Company will arrange for packing of the goods on behalf of the Buyer at an extra charge of @ 10% Inspection Inspection can be carried out at our works prior to dispatch if so desired by you. Dispatch All the Company s goods are forwarded at the Buyer s own risk. In case of goods for export or goods sold delivery ex the Company s Works the Company cannot accept responsibility for damage or delay during transit unless it has specifically agreed in writing to cover such risk by insurance Performance, Weight, Measurement and Power Although carefully computed, must be considered approximate only and are not guarantee. Force Majure If either party is delayed or hindered in or prevented from performing any of its obligations under the Agreement by reason of act of God, fire, flood, accident, explosion, breakdown or failure of plant or machinery, war, riot, civil disturbance, strike, labour dispute, acts, orders, or regulations of Government failure (whether partial or total) of or shortage in any of the Company s or its suppliers existing or contemplated sources of material (including parts & components) or fuel or labour or transport whether such failure or shortage be existing or apprehended by the Company, failure of any supplier or sub-contractor with the Company or by reason of any cause whether or not of the same nature as the foregoing beyond its control, it shall be under no liability to the other in respect of non-performance of such obligation but the time for performing the same shall be extended until the operation of causes preventing, hindering or delaying the performance thereof has ceased. Warranty The offered equipment shall be guaranteed for a period of 12 months from the date of its dispatch against and manufacturing defect only. However, warranty does not cover against misuse, mishandling, improper maintence rubber & electrical parts and brought out items. Special Note Once order is placed the buyer cannot be cancel the order, if cancellation is done no refund of Advance payment would be claimed from seller at any cost. Arbitration 1. All disputes or differences arising in future between the parties relating to this quotation shall be referred for arbitration in accordance with the provisions of the arbitration and conciliation act, 1996 based at Alwar, Rajasthan. The award made in pursuance to that shall be binding on both the parties. The sales against this quotation shall be continued during arbitration proceedings unless it is reasoned that the sales cannot possibly be continued till the matter is finally decided by the appointed arbitrators, no payment due to the company shall be withheld on account of such arbitration proceedings, unless it is the subject matter or one of the subject matters thereof, The supplier shall not pay any interest, damages (including liquidated risk purchase) etc. for non-delivery of material for the reasons beyond its control. 2. Appointment of Arbitrator Each party shall appoint one (1) arbitrator and these two (2) arbitrators shall jointly agree on and appoint the third arbitrator. If the two (2) arbitrators appointed cannot agree on a third arbitrator, the third arbitrator shall be appointed in accordance with the provisions of the arbitrations and conciliation Act, 1996 and any amendment/thereof. 3. The Language of arbitration shall be English only. 4. Binding and Liability. The award pass by the arbitrator(s) shall be binding and the sole and exclusive remedy between the parties regarding any dispute and all claims or counterclaims for the parties, their successors and assign and each shall comply in good faith with any and all rulings of the arbitrators. Installation & Commissioning 1. Exaction of the machine cable laying & termination to be done by the customers as per our specification. 2. Installation, commissioning & servicing under warranty period is free of cost only you have to bear to&Fro AC Train fare along with loading & boarding. 3. After warranty the charges of the engineer is 5000/- per day (A day is considered to be a 8 hours working hour) plus To &Fro AC Train fare with loading & boarding. 4. In case of Export all the expenses (Visa, Air Ticket, Hotel, and Local Fare Ec.) will be charge extra. Validity of the offer 30 days from the date of dispatch. All disputes subject to only Alwar Jurisdiction. [NOTE: ANY OTHER CLAUSE, WHICH IS NOT MENTIONED IN OUR OFFER, SHALL NOT BE BINDING ON US UNLESS AGREED BY US IN WRITING.] Thanking you, & awaiting your valued order. Yours faithfully For Jindal Hydro Projects Inc. Rakesh Gupta +91-986817694

- Asia

- All India

Product Description

Product details

|

Cycle Time without Feeding |

60 to 80 Sec. |

|

Pressed Bale |

12" x 12" x Variable |

|

Type of Loading |

Manually from Top |

|

Electric Motor (hp) |

25 H.P. 1440 R.P.M. 3 Phase, |

|

Oil Tank Capacity (Litre) |

700 Liters |

|

Number of Cylinder |

05 Nos. |

|

Chamber Material |

45" x20"x24" |

Specification

|

Charging Chamber |

45" x20"x24" |

|

Pressed Bale |

12" x 12" x Variable |

|

No. of Hyd. Cylinders |

05 Nos. |

|

Working Pressure |

3000 PSI |

|

Electric Motor |

25 H.P. 1440 R.P.M. 3 Phase, |

|

Oil Drive |

Radial Plunger pump |

|

Oil Tank Capacity |

700 Liters |

|

Cycle Time without Feeding |

60 to 80 Sec. |

|

Weight of Bale (aprox) |

50 to 70 Kg |

|

Hard Plate Lining |

Provided |

|

Shearing blade on both |

|

|

Longitudinal sides of body |

Provided |

|

Type of Control |

push Button Control |

|

Type of Loading |

Manually from Top |

|

Type of Unloading |

Top with the help of Hydraulic ejector |

Advanced Triple Compression Technology

Featuring triple compression with a requirement-based solenoid valve, this machine optimizes pressure application, resulting in higher efficiency and consistent output. The combination of a PLC system and proportional valve provides users with fine-tuned control tailored to specific operational requirements, enhancing safety and productivity in heavy-duty manufacturing processes.

Precise Automation & High Capacity

Incorporating a pre-fill valve and PLC control allows for automated functions, ensuring seamless operation throughout the process. With a high nominal force of 100 TON and a daily capacity of 700 liters, the machine is designed for demanding industrial applications needing both strength and substantial throughput.

FAQs of Triple Compression:

Q: How does the triple compression system with a solenoid valve improve operation?

A: The triple compression system enhances material compaction by applying force in three stages, while the solenoid valve, included as per requirement, allows for precise and reliable control over the hydraulic pressure, resulting in consistent and efficient performance.Q: What is the function of the pre-fill valve and under what circumstances is it required?

A: The pre-fill valve is provided as needed to facilitate rapid filling of the hydraulic system, reducing cycle times. It is particularly beneficial in high-capacity or high-speed applications where quick actuation is essential for productivity.Q: When is the integration of a PLC system necessary for this press?

A: A PLC system is included based on user requirements, enabling automated control, monitoring, and diagnostics. This is especially crucial for complex or repetitive industrial processes that demand accuracy, reliability, and reduced manual intervention.Q: Where can this hydraulic press be used most effectively?

A: This machine is ideally suited for use in manufacturing plants and industrial settings that require high-force operations, such as metal forming, plastic compaction, or other heavy-duty applications, particularly where automation and precision are priorities.Q: What are the advantages of using a proportional valve in this system?

A: The proportional valve, provided as per requirement, enables fine adjustment of hydraulic pressure and flow. This leads to smoother operation, reduced energy consumption, and improved process control, especially during intricate or variable-load tasks.Q: How can users benefit from the robust steel construction and sizable capacity?

A: Constructed from durable steel, the machine ensures longevity and operational resilience. Its 700-liter/day capacity maximizes throughput, making it a reliable choice for businesses seeking to increase productivity without compromising safety or structural integrity.Q: What is the power source and how does it impact usage?

A: Operating on a 25 HP motor with hydraulic power and a 240-volt supply, the press delivers high force and dependable energy efficiency. The hydraulic system ensures continuous pressure, making it ideal for extended use in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese