Call Us

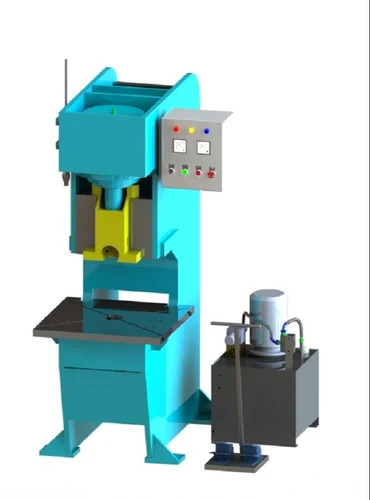

08045811645H Frame Hydraulic Press Machine

700000 INR/Unit

Product Details:

- Nominal Force requirement based

- Usage Industrial

- Power Source Hydraulic

- Size Standard

- Product Type H Frame Hydraulic Press Machine

- Color requirement based

- Motor requirement based

- Click to View more

X

H Frame Hydraulic Press Machine Price And Quantity

- 1 Unit

- 700000 INR/Unit

H Frame Hydraulic Press Machine Product Specifications

- requirement based

- requirement based

- H Frame Hydraulic Press Machine

- requirement based

- Standard

- requirement based

- requirement based

- Hydraulic

- requirement based

- Industrial

- requirement based

- requirement based

H Frame Hydraulic Press Machine Trade Information

- requirement based

- Cash in Advance (CID)

- 10 Unit Per Month

- 1 Months

- Sample costs shipping and taxes has to be paid by the buyer

- poly pack

- Asia

- All India

Product Description

Our company deals in the manufacturing, supplying and exporting of heavy duty H Frame Hydraulic Press Machine which is commonly used in various industries for the punching, blanking and compacting of the waste materials for easy handling. This heavy machinery is capable to produce a large compressive force of 1500 tons with the help of hydraulic drives. It is equipped with a fully automated control panel that makes it very easier to control this machine.

Technical Specifications

|

Capacity (Ton) |

1500 tons |

|

Size |

Standard |

|

Material |

Steel |

|

Automatic Grade |

Automatic |

|

Quality |

High |

|

Machine Type |

Hydraulic |

|

Efficiency |

High |

|

Condition |

New |

Versatile Industrial Application

Engineered for demanding industrial environments, our H Frame Hydraulic Press Machine excels in a wide array of processes, from material forming to precision assembly. Its flexibility makes it ideal for automotive, manufacturing, and metalworking industries, supporting both repetitive tasks and specialized production jobs.

Custom-Configured for Your Needs

With adjustable parameters such as force, PLC controls, motor specification, pressure gauges, and more, the press can be precisely tailored to suit your operational requirements. This level of customization ensures you receive a solution that integrates seamlessly into your workflow for maximum productivity.

FAQ's of H Frame Hydraulic Press Machine:

Q: How does an H Frame Hydraulic Press Machine operate in an industrial setting?

A: The machine uses a hydraulic system to generate controlled force through an H-shaped frame, enabling efficient pressing, forming, or molding processes. Operators can adjust key components like force, pressure gauges, and motor settings to align with specific task requirements.Q: What are the customization options available for this hydraulic press machine?

A: Users can specify nominal force, PLC system configuration, motor power, pressure gauge type, solenoid and proportional valves, pre-fill valve, and overall color. These options allow the press to be tailored for unique industrial applications and capacity needs.Q: When is it beneficial to use a hydraulic press with PLC system integration?

A: PLC system integration is beneficial for automated and complex operations where precision, repeatability, and real-time monitoring are essential. It facilitates enhanced process control, reducing human error and improving efficiency for high-volume industrial applications.Q: Where can the H Frame Hydraulic Press Machine be installed?

A: The machine is suitable for installation in industrial manufacturing plants, fabrication units, automotive workshops, and metalworking facilities. As an exporter, manufacturer, and supplier based in India, we provide support for installation across domestic and international locations.Q: What is the process for sourcing a requirement-based hydraulic press from your company?

A: Customers can share their specific operational requirements with us, including force, size, controls, and other desired features. Our team evaluates these needs and develops a tailored machine configuration, guiding clients from selection to delivery and setup.Q: What are the key benefits of using an H Frame Hydraulic Press Machine in industrial operations?

A: Benefits include high efficiency, customizable functions, robust construction for durability, and adaptability to a broad spectrum of industrial tasks. The machine's hydraulic system ensures consistent performance, contributing to reliable production quality and reduced downtime.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hydraulic Presses' category

"We are mainly looking for International Inquiries. We are looking for more inquires related to balling products"

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free