Call Us

08045811645Jumbo Industrial Power Pack

100000.00 - 150000.00 INR/Unit

Product Details:

- Connectivity Type Threaded or Flanged Connections

- Sealing Type High Quality Seals, Leak Proof

- Accessories Pressure Gauge, Filters, Return Line, Suction Line, Level Gauge

- Application Industrial Hydraulic Systems, Presses, Lifts, Heavy Machinery Automation

- Flow Rate Up to 200 LPM

- Efficiency High Efficiency Motor and Pump

- Temperature Range -10C to +80C

- Click to View more

X

Jumbo Industrial Power Pack Price And Quantity

- 100000.00 - 150000.00 INR/Unit

- 1 Unit

Jumbo Industrial Power Pack Product Specifications

- Pressure Gauge, Filters, Return Line, Suction Line, Level Gauge

- Mild Steel

- Industrial Hydraulic Systems, Presses, Lifts, Heavy Machinery Automation

- High Quality Seals, Leak Proof

- Up to 200 LPM

- 220V/380V/415V AC

- Threaded or Flanged Connections

- Compact and Rigid

- High Efficiency Motor and Pump

- -10C to +80C

- Industrial Power Pack

- Up to 350 Bar

- Easy Maintenance, Sturdy Design, Corrosion Resistant, Energy Efficient

- Electric

- High Force Output Suitable for Heavy Duty Machinery

- Customizable Output Speed

- Base Mounted or Customized

Jumbo Industrial Power Pack Trade Information

- 10 Unit Per Month

- 1 Months

Product Description

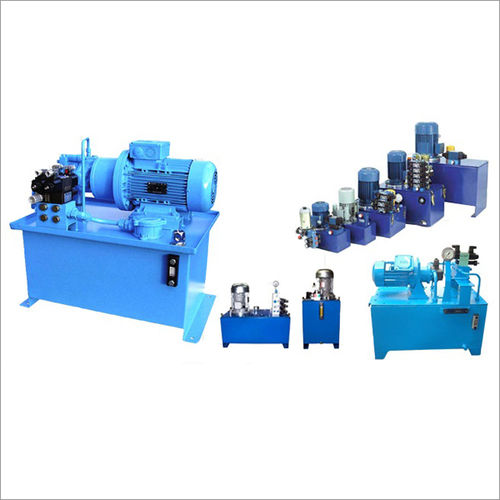

Jumbo Industrial Power Pack offered by us, is a complete hydraulic system that includes pumps, valves, motors, and other components. This power pack is created and manufactured in-house using cutting-edge technology, allowing us to compete globally. This product is tailored to the needs of the customer. Apart from this, Jumbo Industrial Power Pack can also be equipped with electrical relays, PLCs, and CNC control systems. This pack is very cost-effective and can be easily purchased by our eminent customers, at nominal pricing.Customizable Performance for Diverse Needs

Choose from a range of oil tank capacities (5002000 litres), pump types, and motor powers (5100 HP) to tailor the power pack to your specific operation. Compact yet robust, its suitable for presses, lifts, and automation of heavy machinery.

Engineered Safety and Durability

Safety is at the forefront, with overload protection, an emergency stop switch, and high-quality leak-proof seals. Manufactured from mild steel with industrial-grade powder coating, this power pack is corrosion resistant and built for longevityeven in demanding environments.

Easy Operation and Maintenance

With options for manual or PLC controls, and features like accessible filters, gauges, and lines, daily operation and servicing are simplified. Optional portability through skid or frame mounting further enhances convenience and workplace flexibility.

FAQs of Jumbo Industrial Power Pack:

Q: How can I customize the Jumbo Industrial Power Pack for my application?

A: You can select the oil tank capacity (from 500 to 2000 litres), pump type (gear, vane, or piston), motor power (5 HP to 100 HP), cooling system (air or water), and control system (manual or PLC). Additional customization includes portability (skid or frame mounting), mounting type, and output speed adjustments.Q: What industries or applications is this power pack suitable for?

A: The Jumbo Industrial Power Pack is ideal for use in industrial hydraulic systems, presses, lifts, automation of heavy machinery, and other heavy-duty applications where reliable, high-force output is needed.Q: When should routine maintenance be performed on the power pack?

A: Routine maintenance should be conducted based on usage intensity, typically every 36 months. Key tasks include inspecting seals, changing filters, checking oil levels, and monitoring for leaks or abnormal noises.Q: Where should this power pack be installed for optimal performance?

A: Install the power pack on a stable, level surface in a well-ventilated area. Opt for locations that allow convenient access for maintenance and are protected from extreme temperatures or corrosive environments. Skid or frame mounting enhances portability if workspace flexibility is needed.Q: What is the process for setting up and starting the power pack?

A: Installation involves securing the unit, connecting hydraulic lines and electrical supply per the voltage requirement, filling the tank with suitable hydraulic oil, and ensuring all accessories (filters, gauges) are correctly fitted. Final steps include performing safety checks and initiating operation through manual or PLC controls.Q: How does the power pack ensure user safety during operation?

A: The system is equipped with overload protection, an emergency stop switch, and high-quality sealing to prevent leaks. These features, along with PLC/manual control options, provide multiple safety layers for operator protection during use.Q: What benefits does the Jumbo Industrial Power Pack offer over standard models?

A: This model offers high efficiency, low noise operation, and customizable performance. Its robust design, superior cooling options, and enhanced safety features make it a reliable, energy-efficient choice for demanding industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hydraulic Power Pack' category

"We are mainly looking for International Inquiries. We are looking for more inquires related to balling products"

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free