Call Us

08045811645Mini Power Pack

Product Details:

- Temperature Range -10C to 60C Celsius (oC)

- Operating Pressure Up to 220 bar Bar

- Accessories Oil Level Indicator, Suction Strainer, Pressure Gauge

- Features Portable, Compact, Low Noise, Easy Maintenance

- Flow Rate Up to 10 LPM

- Application Hydraulic Lifts, Tippers, Scissor Lifts, Presses, Material Handling Equipment

- Efficiency High Efficiency Motor

- Click to View more

Mini Power Pack Price And Quantity

- 250000 INR/Unit

- 1 Unit

Mini Power Pack Product Specifications

- Compact Mini Unit

- Oil Level Indicator, Suction Strainer, Pressure Gauge

- 12 25 mm/s (customizable) mm/m

- Up to 220 bar Bar

- -10C to 60C Celsius (oC)

- Hydraulic Power Pack

- Hydraulic Lifts, Tippers, Scissor Lifts, Presses, Material Handling Equipment

- Up to 10 LPM

- Portable, Compact, Low Noise, Easy Maintenance

- Base Mount

- Up to 1000 kg (varies with application)

- Mild Steel

- High Efficiency Motor

- High-grade Synthetic Rubber

- 12V / 24V / 220V AC Volt (v)

- Electric

- Hydraulic Hose Connectors

Mini Power Pack Trade Information

- 10 Unit Per Month

- 1 Months

Product Description

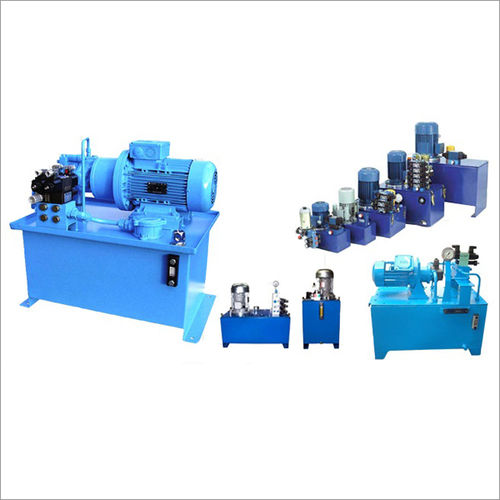

Mini Power Pack

This Hydraulic Mini Power Pack Is Used for Smooth Operation of Automobile Tail Gate, Scissors Lift, Vehicle Lift, Semi Electric Stacker and Aerial Platform. This Power Pack Is Equipped With Necessary Parts Like Powerful Motor With Standard Rotation Speed and Hydraulic Oil Tank With Iron Made Structure. This System Uses Direct Current or Ac as Its Source of Power. Small in Shape, This Light Weight Hydraulic Product Is Appreciated for Its Long Working Life, Ergonomic Shape, Sturdy Construction and Ease of Installation. This Array of Power Pack Uses Cutting Edge Flow Controlling System for Its Functional Stability. This Low Noise Hydraulic Equipment Can Be Availed in Different Specifications. We Are a Successful Exporter and Manufacturer of Best Grade Mini Power Pack.

This mini power pack dimensions are very small and compact, so, we also call them small hydraulic power packs or small hydraulic power units. They offer high pressure with low flow for single action hydraulic systems or double acting small hydraulic cylinders.

Typical Mini Pack applications include :

- Waste Compactor/Balers

- Tipping Trucks and Trailers

- Lifts (Direct and Scissor)

- Road Blockers and Bollards

- Industrial machines

- JINDAL HYDRO PROJECTS INC. have a proven record of performance.

- 100% testing

- Wide application knowledge

- Large stock holding

- Fast deliveries

- Product support

- Ability to tailor designs

- Global customer base

- 3D modelling facilities

Compact & Portable Design

The Mini Power Packs structure is engineered to be space-saving and easy to transport, weighing approximately 15 to 35 kg. Its base mount makes installation straightforward, and the compact size allows it to fit effortlessly into tight spaces while retaining robust power and high efficiency.

Versatile Application & Customization

This hydraulic power pack is suitable for multiple hydraulic applications, including hydraulic lifts, tippers, scissor lifts, and presses. With adjustable force, speed, and voltage (12V, 24V, 220V AC), it meets a range of operational needs while offering tailored performance for unique requirements.

Durability & Low Maintenance

Constructed from industrial-grade mild steel, the unit provides long-lasting durability. Integrated features such as a return line filter and high-grade synthetic rubber seals reduce maintenance frequency and extend operational life. Its IP54 rating ensures protection against dust and moisture, even in demanding environments.

FAQs of Mini Power Pack:

Q: How does the Mini Power Pack ensure efficient hydraulic operation?

A: The Mini Power Pack utilizes a high-efficiency electric motor paired with a reliable gear pump. This allows it to deliver consistent hydraulic pressure and flow while maintaining low noise levels and energy consumption.Q: What is the typical process for installing and connecting the Mini Power Pack?

A: Installation involves base mounting the unit, connecting the hydraulic hose connectors to the desired application, and powering the pack to a suitable electric supply (12V, 24V, or 220V AC). Its compact form and integrated accessories make connection and start-up quick and straightforward.Q: Where can the Mini Power Pack be used most effectively?

A: It is highly effective in hydraulic lifts, tippers, scissor lifts, presses, and a variety of material handling equipment used in industrial and commercial settings requiring compact hydraulic solutions.Q: When is it beneficial to choose a Mini Power Pack over a standard hydraulic power pack?

A: Opt for this mini unit when space is limited, portability is essential, or applications require moderate hydraulic force (up to 1000 kg) and lower flow rates (up to 10 LPM), such as in mobile equipment or compact machinery.Q: What steps are involved in maintaining the Mini Power Pack?

A: Regular maintenance includes checking the oil level using the integrated indicator, inspecting the suction strainer, and ensuring the return line filter is clean. Occasional checks on synthetic rubber seals and hose connectors help prevent leaks and prolong operational life.Q: How does the integrated return line filter benefit users?

A: The built-in return line filter captures contaminants from the returning hydraulic fluid, protecting internal components, reducing downtime, and extending the lifespan of the power pack.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free